- Chile | 27 September 2022

Can you provide an introduction to TAKRAF and its operations?

TAKRAF is a company that specializes in mining, bulk material handling, and solid-liquid separation equipment and systems. Our operations span across 15 countries, with offices in Canada, US, Mexico, Brazil, Peru, and Chile in the Americas. Our headquarters is located in Leipzig, Germany, which is home to the company’s technological center for management systems, and we also have a large technical center in India. Our focus is on customizing technology and equipment to meet our customer’s needs rather than developing products to introduce to the market. Collaboration with our clients is an essential aspect of our work, and we aim to reduce investment costs and operating costs. Another area of focus is automation, where we are incorporating artificial intelligence to enhance safety and optimize operations.

Can you provide an example of TAKRAF’s work with a mining company in Chile?

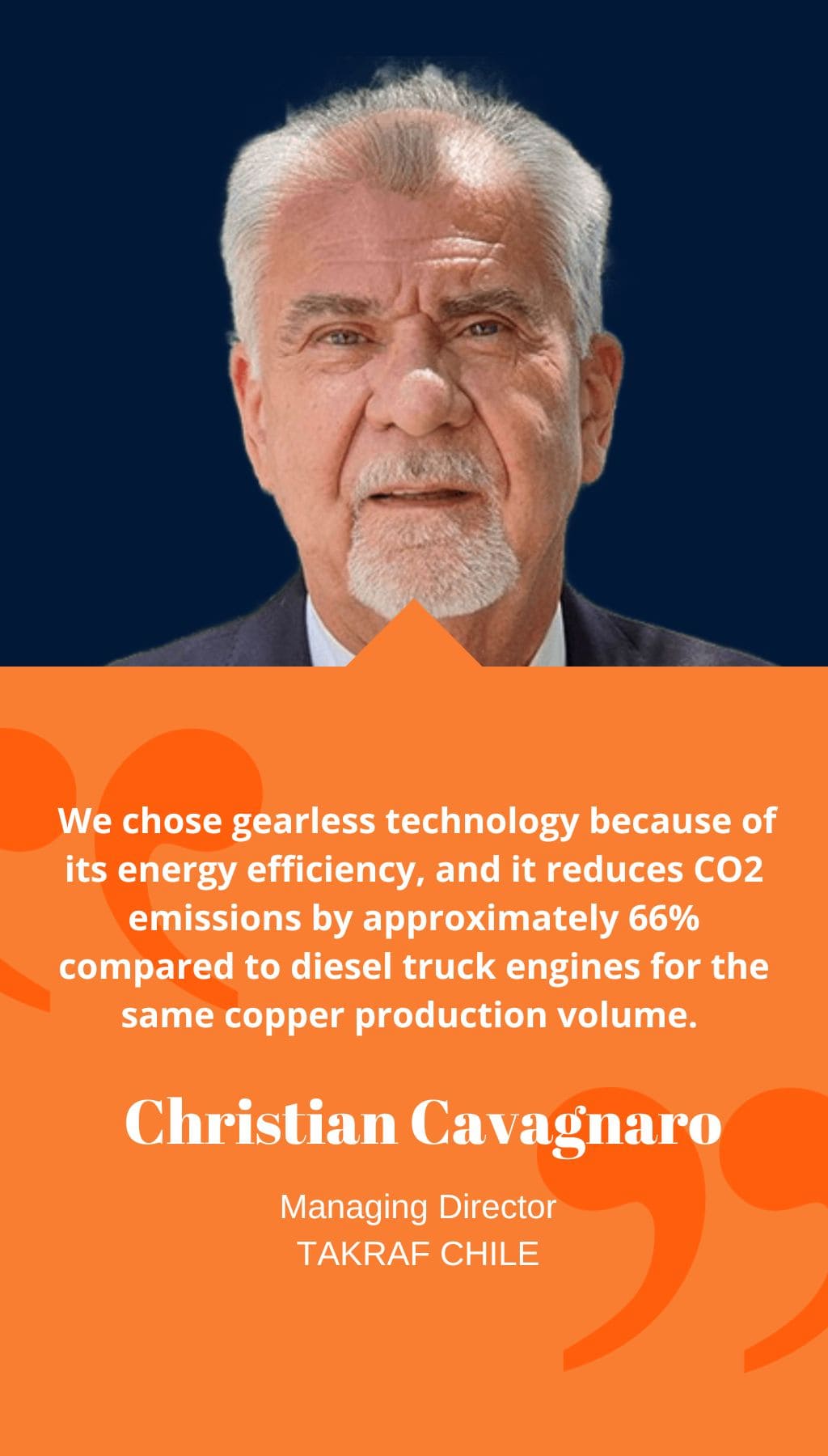

We worked on Codelco’s Chuquicamata underground mine, which is an outstanding project that required a significant amount of work to lower operating costs and reach the deposit. We installed a high-power, high-capacity conveyor belt system, incorporating gearless drive technology. We installed two inclined belts covering a distance of 7 km, each consisting of four 5 MW gearless motors, that overcame the roughly 1 km vertical elevation to the surface. We also installed a 6 km overland conveyor with a capacity of 15 MW. We chose gearless technology because of its energy efficiency, and it reduces CO2 emissions by approximately 66% compared to diesel truck engines for the same copper production volume. Gearless technology also has low operational costs, requiring much less maintenance. Our belt technology partner also developed a new, ST10000 tension range belt to transport the material under such an extreme conveying solution. This project achieves a number of world firsts boasting the highest conveyor drive power of 58 MW and the strongest resistance belt in the world.

Can you explain how bulk material handling or processing facilities can improve the environmental aspects of a mining operation?

Two crucial aspects of sustainability that material handling systems play a critical role in are noise reduction and dust contamination. Conveyors are an equipment that removes dust contamination, whereas trucks, for example, do not. Additionally, conveyor belts use electrical energy, which can be obtained from renewable sources, whereas traditional forms of transportation use fuels that generate carbon emissions.

How do TAKRAF’s stockpiling and loading/unloading of saleable material services help companies overcome supply chain and logistics complications?

TAKRAF’s product portfolio has systems and equipment that enable the storage of large quantities of stockpiles. In Brazil, for instance, we transport a type of ground sugar cane used as fuel for energy generation plants, not just ore. Additionally, we have ship-loaders that specialize in loading and unloading large tonnage and high-tech vessels. As an example, we were selected to supply essential material handling equipment, such as a wagon unloading station and ship loader, for a bulk terminal expansion project in Canada.

What is your outlook for mining equipment opportunities in Chile in the years ahead?

With the high level of uncertainty that exists, it is difficult to have a concrete answer. However, as humanity continues to grow, water, food, metals, and minerals have to be produced, and the production of minerals will increase due to electromobility. Chile will play a significant role in this transition as a major global producer of copper and lithium. Our Group also sees a lot of opportunities to implement high-tech solutions that will enable this production, particularly in underground settings, which require innovation to become economic, safe, and efficient.